SELF-ASSEMBLING SYSTEMS

In 2017, I received a Shapeways Education Grant to 3D print systems that self-assemble from a disordered jumble into complex, specific arrangements. In my senior year, I designed and built several projects with self-assembling or self-arranging properties to explore their limits and practicality. I made systems ranging from cubes that self-assemble into a specific pattern to a physical representation of the XY model for classical spins. My final project, a self-assembling LED circuit, is shown in the video to the left. It uses patterns of magnets on each contacting surface to mandate that, of the 96 possible ways for pieces to link, only the 4 desired ways occur.

This cube rapidly unfolds and assembles when released due to gravity. It is printed entirely as one piece; it was interesting designing hinges and sliding parts that could be printed already assembled. Though the parts don't align perfectly, the design could be modified so they do. This idea could be used to make more intricate objects like collapsible furniture or tents.

GRAVITY-ASSEMBLING CUBE

This prototype shows that it is possible to make electronics that self-assemble from basic components. Imagine a future situation where an organization like a military or a first-responder group might quickly need a large number of any of a variety of different small electronics like flashlights, location trackers, pulse monitors,or gas sensors. Instead of carrying lots of every possible device, that group might be able to just choose the right constituent components, shake them in a vat, and take out assembled devices. The process of choosing components and letting random interactions combine them would be like doing chemistry with electronics instead of molecules.

An earlier system that uses magnetic patterns to assemble into a rod

EMBEDDING MAGNETS

These structures are made from simple identical units, each with four springs and four magnets, one at each end. The magnets are oriented so that adjacent magnets have opposite poles facing out, and this property actually lets them make any orientable surface. The weakness of the magnetic links and the flexibility of the springs lets these structures break to allow objects through and heal themselves afterwards.

This past summer, as an intern at NIST in Boulder, it struck me that gears might work with magnets instead of contacting teeth. After talking with other interns, I designed these frictionless, contactless magnetic gears. Though they can only transfer a small amount of torque, they could do so across a vacuum.

BALANCING SCULPTURES

These are sets of 3D-printed objects that balance together as mobiles. I calculated the physics for each; the blue sculpture in the bottom right needed three prints to balance (the second is shown here), but, after those experiments, the other sculptures all balanced the first time. All are surprisingly stable; you can easily walk with one balanced on your finger. I like how visible the pieces’ interactions are.

MISCELLANEOUS PROJECTS

PUZZLES

The object to the right is a 5x5x5 cubic maze that you can turn to move a ball around in. I 3D printed it, but instead of making the file for it by hand, I wrote a Python program that generates an OpenSCAD program that makes the model. This system can randomly generate printable 10x10x10 mazes.

The object to the left is a 3D-printed ball maze with two levels. The maze seems impossible at first glance; its solution involves going under a bridge, down a ramp, and through the lower level, navigating from channels cut through the entirety of the maze from above.

The object to the left is a 3D-printed ball maze with two levels. The maze seems impossible at first glance; its solution involves going under a bridge, down a ramp, and through the lower level, navigating from channels cut through the entirety of the maze from above.

I crafted this object for a puzzle hunt for my dorm. The disk to the left was inscribed with 'N,' 'E,' 'S,' and 'W' around its circumference like a compass. It was given to hunters with a clue that was something like "the answer will reveal itself at dawn."

When a light is shined from the east side of the disk at the right angle, the shadows spell 'hrc,' the name of a building where a prize was hidden.

I wanted to see if I could make a program that randomly generates trees. This is one result. It was fun experimenting with it, watching a program I’d made chaotically building trees of different structures and depths.

CHAOS TREE

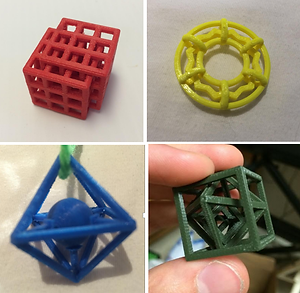

IMPOSSIBLE GEOMETRIES

Because 3D printers build layer by layer, not inside outward, they can make convoluted things near impossible to make otherwise. Intricacy doesn’t necessarily make an object harder to print. My first thought when I heard of 3D printing with support material was that you could make impossible stuff.

That’s what I made as soon as I had printer access; seven of the first ten objects I printed were ricochets of that initial thought.